Welcome to visit the website of Sanmo Precision Machinery (Kunshan) Co., Ltd

whats app: +86 15599099006 / +86 15599099098

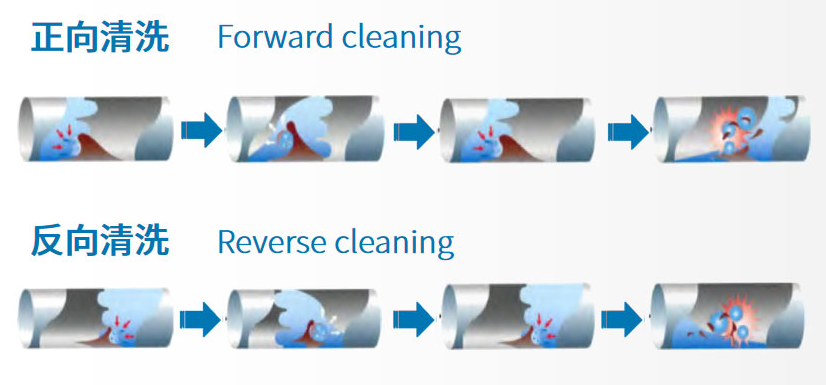

The Shanmo Mold water cleaning machine utilizes patented technology. A pulse controller directs compressed air in pulses onto the water flow, generating a spiral shearing force along the inner wall of the pipe and frequently inducing cavitation.

Under alternating pressure, water bubbles burst, generating micro-jet and shock wave impacts. These jets exert a powerful impact on solid surfaces, causing localized surface damage. The jets and the waves generated by bursting bubbles act on the solid surface at high speed and pressure, eroding and removing scale and brittle fragments, effectively cleaning the inner wall of the pipe.

Working Principle of the Mold Water Cleaning Machine

The Shanmo mold water cleaning machine utilizes patented technology. A pulse controller directs compressed air in pulses onto the water flow, generating a spiral shearing force along the inner wall of the pipe and frequently inducing cavitation.

Under alternating pressure, water causes bubbles to burst, generating micro-jet impacts and shock wave impacts. These jets can exert a huge impact on the solid surface and cause local surface damage. The jets and the waves generated by the bursting bubbles act on the solid surface at high speed and high pressure, eroding it, removing scale and brittle fragments, and effectively cleaning the inner wall of the pipe.

Product Model

A Mold water channel cleaning machine is a device used for cleaning the water channels of molds, commonly used in industries such as automotive manufacturing and home appliance manufacturing. The working principle of a mold water channel cleaning machine is to use high-pressure water jets to clean dirt and impurities from the mold, ensuring its usability.

A mold water channel cleaning machine typically consists of a main machine, a water channel system, a control system, and nozzles. The main machine is the core component, responsible for providing the cleaning water pressure and flow rate, driving the entire cleaning process. The water channel system refers to the piping system connecting the main machine and the mold water channels, delivering high-pressure water to the mold water channels. The control system controls the start-up, shutdown, and operation of the cleaning machine, ensuring smooth cleaning. The nozzles are a key component of the cleaning machine, cleaning the mold by spraying high-pressure water jets.

The working process of a mold water channel cleaning machine generally involves the following steps: First, preparation, including placing the mold inside the cleaning machine, connecting the water channel system and power supply, and setting the cleaning parameters. Next, the cleaning machine is started, with the control system activating the main machine and controlling the nozzles to spray high-pressure water jets. Next comes the cleaning process, where high-pressure water jets flush the mold's water channels, removing dirt and impurities. Finally, the work is finished; the cleaning machine is turned off, and the mold is removed for inspection.

The advantages of a mold water channel cleaning machine include excellent cleaning effect, high efficiency, and simple and convenient operation. It can quickly clean dirt from the mold's water channels, improving mold lifespan and production efficiency, while reducing maintenance costs and time. Furthermore, the mold water channel cleaning machine is energy-saving and environmentally friendly, using water as the cleaning medium and producing no waste gas or waste liquid, meeting environmental protection requirements.

In summary, the mold water channel cleaning machine is a highly effective mold cleaning device with significant application value for industries requiring mold water channel cleaning. With the development of manufacturing and the increasing demand for molds, mold water channel cleaning machines will receive increasing attention and become an indispensable cleaning equipment in the manufacturing industry.

Mold maintenance is a critical factor in high-precision manufacturing sectors such as injection molding, die casting, and electronics production. Over time, molds accumulate residues, oxidation layers, and micro-deposits that compromise part quality, reduce heat transfer efficiency, and lead to production downtime. Traditional cleaning methods, such as manual scraping, high-pressure washing, or abrasive techniques, often damage the mold surface, introduce inconsistencies, and increase labor costs. Consequently, there is a growing demand for industrial mold cleaning equipment that delivers consistent, safe, and efficient cleaning while preserving mold integrity, supporting high-volume production, and minimizing operational interruptions.

Industrial mold cleaning equipment is designed to remove contaminants from mold surfaces without mechanical damage. The most widely used technologies include:

Water-based cleaning systems: Utilize high-pressure or circulating water combined with detergents to remove residues.

Ultrasonic cleaning: Employs high-frequency sound waves in a liquid medium to generate cavitation, effectively dislodging deposits from complex geometries.

Electrolytic cleaning: Uses controlled electrochemical reactions to remove oxides and corrosion without abrasive contact.

These systems rely on precise chemical formulations, controlled temperature, and flow rates to ensure uniform cleaning across all mold surfaces. The integration of nano-scale additives or surfactants can further enhance penetration into micro-crevices and intricate mold features, ensuring complete cleaning without altering dimensions.

Industrial mold cleaning equipment generally consists of a cleaning chamber or tank, circulation and filtration systems, heating and temperature control units, and automated or semi-automated handling mechanisms. Materials used in construction typically include corrosion-resistant stainless steel or coated alloys to withstand prolonged exposure to cleaning solutions and water. Performance indicators include:

Cleaning efficiency across diverse mold geometries

Preservation of surface finish and tolerances

Consistent chemical stability and flow distribution

Energy consumption and operational cost-effectiveness

Manufacturing of these systems requires precise assembly, robust component selection, and stringent quality control to ensure reliability and longevity in industrial environments.

Several operational and environmental factors affect the efficacy of industrial mold cleaning equipment:

Mold material: Steel, aluminum, and coated molds respond differently to cleaning agents and processes.

Contaminant type: Residues, scale, or corrosion layers require specific cleaning approaches.

Application method: Spraying, dipping, or circulation systems must be properly configured for complete surface coverage.

Temperature and chemical concentration: Optimal ranges are critical to prevent surface degradation while achieving effective cleaning.

Proper monitoring and calibration of these variables ensure repeatable results, extending mold lifespan and maintaining part quality.

Selecting a reliable supplier for industrial mold cleaning equipment involves evaluating:

Technical support: Guidance on system setup, chemical selection, and troubleshooting.

Compliance and certification: ISO 9001 quality standards and adherence to safety and environmental regulations.

Availability of replacement parts and maintenance services: Ensures minimal downtime and continuous operation.

Customization capabilities: Ability to accommodate unique mold sizes, geometries, or production volumes.

A strong supplier relationship enhances operational efficiency and ensures consistent cleaning performance over the equipment’s service life.

Despite technological advances, manufacturers face recurring challenges with mold cleaning:

Incomplete cleaning of complex cavities and cooling channels

Surface damage from abrasive or high-pressure methods

Chemical waste disposal and environmental compliance

Integration with production schedules without causing downtime

Modern industrial mold cleaning equipment addresses these issues through automated processes, neutral or environmentally safe cleaning agents, and precise control over operating parameters.

Injection molding: Cooling channels and cavities are prone to residue accumulation, affecting thermal efficiency. Industrial mold cleaning equipment restores surface condition without compromising tolerances.

Die casting: Oxide and residue buildup on dies can reduce part accuracy; automated cleaning ensures consistent performance and reduces scrap rates.

Precision components manufacturing: Small or intricate molds benefit from ultrasonic or electrolyte-assisted cleaning to remove deposits without damaging fine features.

The equipment supports high-volume operations by reducing manual labor and ensuring uniform cleaning results.

Industrial mold maintenance is evolving toward:

Automation and integration: Robotic handling and automated dosing systems reduce human intervention and improve consistency.

Nano-enhanced and eco-friendly cleaning agents: Increase penetration efficiency while minimizing environmental impact.

Real-time monitoring and process optimization: Sensors and software allow adaptive cleaning cycles, reducing chemical use and energy consumption.

Sustainable practices: Focus on waste reduction, chemical recyclability, and compliance with global environmental standards.

Investing in modern industrial mold cleaning equipment aligns with these trends, improving operational efficiency, product quality, and sustainability.

Q1: Can industrial mold cleaning equipment handle different mold materials?

Yes, most systems are compatible with steel, aluminum, and coated molds, but testing is recommended for specialized alloys.

Q2: Is pre-cleaning required?

Removing loose debris and large residues enhances efficiency and ensures uniform results.

Q3: How is waste solution managed?

Used cleaning fluids should be treated or neutralized according to local environmental regulations.

@2024 Shanmo Precision Machinery (Kunshan) Co., Ltd. All rights reserved. Mold waterway cleaning machine,

electrolytic mold cleaning machine, mold cleaning machine manufacturer

TEL:+86 512-55001520

whats app:+86 15599099006 / +86 15599099098

E-Mail:sanmo030788@gmail.com

Add:No. 56, Yangjiaqiao Road, Zhoushi Town, Kunshan City Jiangsu Province

This website uses cookies to ensure you get the best experience on our website.