Welcome to visit the website of Sanmo Precision Machinery (Kunshan) Co., Ltd

whats app: +86 15599099006 / +86 15599099098

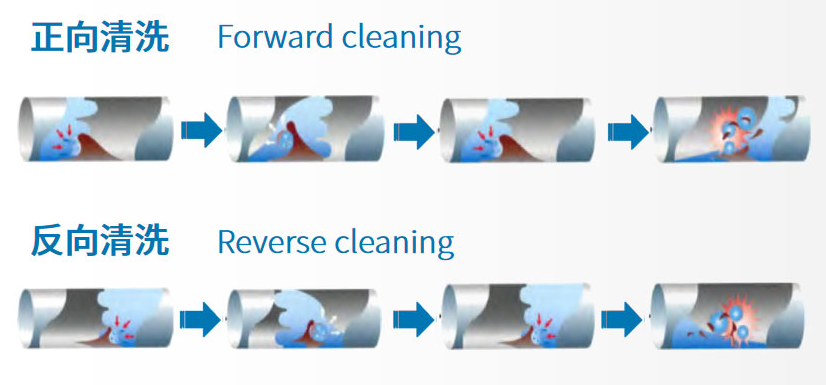

The Shanmo Mold water cleaning machine utilizes patented technology. A pulse controller directs compressed air in pulses onto the water flow, generating a spiral shearing force along the inner wall of the pipe and frequently inducing cavitation.

Under alternating pressure, water bubbles burst, generating micro-jet and shock wave impacts. These jets exert a powerful impact on solid surfaces, causing localized surface damage. The jets and the waves generated by bursting bubbles act on the solid surface at high speed and pressure, eroding and removing scale and brittle fragments, effectively cleaning the inner wall of the pipe.

Working Principle of the Mold Water Cleaning Machine

The Shanmo mold water cleaning machine utilizes patented technology. A pulse controller directs compressed air in pulses onto the water flow, generating a spiral shearing force along the inner wall of the pipe and frequently inducing cavitation.

Under alternating pressure, water causes bubbles to burst, generating micro-jet impacts and shock wave impacts. These jets can exert a huge impact on the solid surface and cause local surface damage. The jets and the waves generated by the bursting bubbles act on the solid surface at high speed and high pressure, eroding it, removing scale and brittle fragments, and effectively cleaning the inner wall of the pipe.

Product Model

A Mold water channel cleaning machine is a device used for cleaning the water channels of molds, commonly used in industries such as automotive manufacturing and home appliance manufacturing. The working principle of a mold water channel cleaning machine is to use high-pressure water jets to clean dirt and impurities from the mold, ensuring its usability.

A mold water channel cleaning machine typically consists of a main machine, a water channel system, a control system, and nozzles. The main machine is the core component, responsible for providing the cleaning water pressure and flow rate, driving the entire cleaning process. The water channel system refers to the piping system connecting the main machine and the mold water channels, delivering high-pressure water to the mold water channels. The control system controls the start-up, shutdown, and operation of the cleaning machine, ensuring smooth cleaning. The nozzles are a key component of the cleaning machine, cleaning the mold by spraying high-pressure water jets.

The working process of a mold water channel cleaning machine generally involves the following steps: First, preparation, including placing the mold inside the cleaning machine, connecting the water channel system and power supply, and setting the cleaning parameters. Next, the cleaning machine is started, with the control system activating the main machine and controlling the nozzles to spray high-pressure water jets. Next comes the cleaning process, where high-pressure water jets flush the mold's water channels, removing dirt and impurities. Finally, the work is finished; the cleaning machine is turned off, and the mold is removed for inspection.

The advantages of a mold water channel cleaning machine include excellent cleaning effect, high efficiency, and simple and convenient operation. It can quickly clean dirt from the mold's water channels, improving mold lifespan and production efficiency, while reducing maintenance costs and time. Furthermore, the mold water channel cleaning machine is energy-saving and environmentally friendly, using water as the cleaning medium and producing no waste gas or waste liquid, meeting environmental protection requirements.

In summary, the mold water channel cleaning machine is a highly effective mold cleaning device with significant application value for industries requiring mold water channel cleaning. With the development of manufacturing and the increasing demand for molds, mold water channel cleaning machines will receive increasing attention and become an indispensable cleaning equipment in the manufacturing industry.

As manufacturing sectors such as automotive, medical devices, electronics, and packaging move toward higher precision and tighter tolerance control, mold maintenance has become a strategic production factor rather than a routine task. Modern molds incorporate complex geometries, micro-scale cooling channels, and multi-material inserts that are highly sensitive to contamination. Residues from processing materials, mineral scale from cooling water, and corrosion byproducts gradually reduce heat transfer efficiency and surface quality. These challenges have driven increasing demand for Precision mold cleaning machine solutions that can deliver consistent, repeatable cleaning without damaging critical mold features.

A precision mold cleaning machine is designed to remove internal and external mold contaminants through controlled, process-driven methods. Unlike manual cleaning or abrasive techniques, these systems rely on regulated fluid circulation, chemical compatibility, and precise parameter control. Key technologies include programmable flow control, temperature stabilization, filtration, and monitoring of cleaning conditions. Some systems incorporate ultrasonic assistance or electrolytic reactions to enhance deposit removal in complex or narrow channels. The objective is to restore mold performance while maintaining dimensional integrity and surface finish.

The structure of a precision mold cleaning machine typically includes a circulation unit, control module, filtration system, and fluid management components. Materials selected for construction prioritize chemical resistance and durability, often using stainless steel, reinforced polymers, and sealed electrical enclosures. Performance metrics focus on cleaning uniformity, pressure stability, and compatibility with various mold materials such as tool steel, aluminum alloys, and copper components. During manufacturing, quality control processes include pressure testing, electrical safety validation, and flow calibration to ensure reliable operation under industrial conditions.

Cleaning effectiveness depends on multiple interrelated factors. The composition of deposits—whether mineral scale, polymer residue, or corrosion—determines the appropriate cleaning method and agent selection. Channel length, diameter, and geometry influence flow dynamics and pressure requirements. Improper temperature control can reduce cleaning efficiency or increase corrosion risk. Additionally, operator-defined parameters and maintenance of filtration components play a significant role in achieving consistent results. A well-configured precision mold cleaning machine balances these variables to deliver predictable performance.

Selecting a suitable equipment supplier requires careful evaluation beyond basic specifications. Buyers should consider the supplier’s technical understanding of mold structures, availability of compatible cleaning agents, and ability to provide application guidance. Documentation quality, compliance with regional safety standards, and long-term availability of spare parts are critical. For global manufacturers, service responsiveness and stable supply chains reduce operational risk and support integration into preventive maintenance programs.

One of the most common challenges in mold maintenance is the lack of visibility into internal cooling channel conditions. Performance degradation often goes unnoticed until cycle times increase or quality defects appear. Traditional cleaning methods may be inconsistent, relying heavily on operator experience. Over-aggressive cleaning can damage surfaces, while insufficient cleaning leaves deposits behind. Precision mold cleaning machine systems address these issues by standardizing procedures and enabling measurable, repeatable outcomes.

In automotive molding operations, precision cleaning supports stable cycle times across high-cavity molds used in continuous production. Electronics manufacturers rely on precise mold temperature control to maintain dimensional accuracy in thin-wall components. In medical device manufacturing, validated cleaning processes are essential to meet regulatory and quality requirements. Across these applications, automated and controlled cleaning reduces downtime and extends mold service life.

The industry is shifting toward intelligent cleaning systems that integrate data monitoring and predictive maintenance. Advanced precision mold cleaning machine designs increasingly feature sensor-based feedback and digital interfaces for process tracking. Environmental considerations are also influencing development, with reduced chemical consumption and closed-loop fluid systems becoming more common. Future innovations are expected to focus on adaptive cleaning algorithms and compatibility with advanced mold designs, including additive-manufactured cooling channels.

How often should molds be cleaned using precision equipment?

Intervals vary based on water quality and production volume, but many facilities adopt condition-based schedules using pressure or temperature monitoring.

Is precision cleaning safe for delicate mold surfaces?

When properly configured, controlled cleaning methods minimize mechanical and chemical stress on mold materials.

Can these systems support preventive maintenance programs?

Yes, standardized cleaning cycles and documented parameters make them well suited for structured maintenance strategies.

Precision mold cleaning machine solutions have become essential tools for maintaining performance, reliability, and quality in modern manufacturing environments. By combining controlled processes with engineering-focused design, these systems support consistent mold operation and align with the increasing demands of high-precision production.

@2024 Shanmo Precision Machinery (Kunshan) Co., Ltd. All rights reserved. Mold waterway cleaning machine,

electrolytic mold cleaning machine, mold cleaning machine manufacturer

TEL:+86 512-55001520

whats app:+86 15599099006 / +86 15599099098

E-Mail:sanmo030788@gmail.com

Add:No. 56, Yangjiaqiao Road, Zhoushi Town, Kunshan City Jiangsu Province

This website uses cookies to ensure you get the best experience on our website.