Welcome to visit the website of Sanmo Precision Machinery (Kunshan) Co., Ltd

whats app: +86 15599099006 / +86 15599099098

With advancements in industrial automation and rising labor costs, market demands for products are becoming increasingly stringent, and manufacturers are placing greater emphasis on controlling pass rates and hidden costs. This has led to the rise of cleaning machines that help improve product quality and enhance competitiveness.

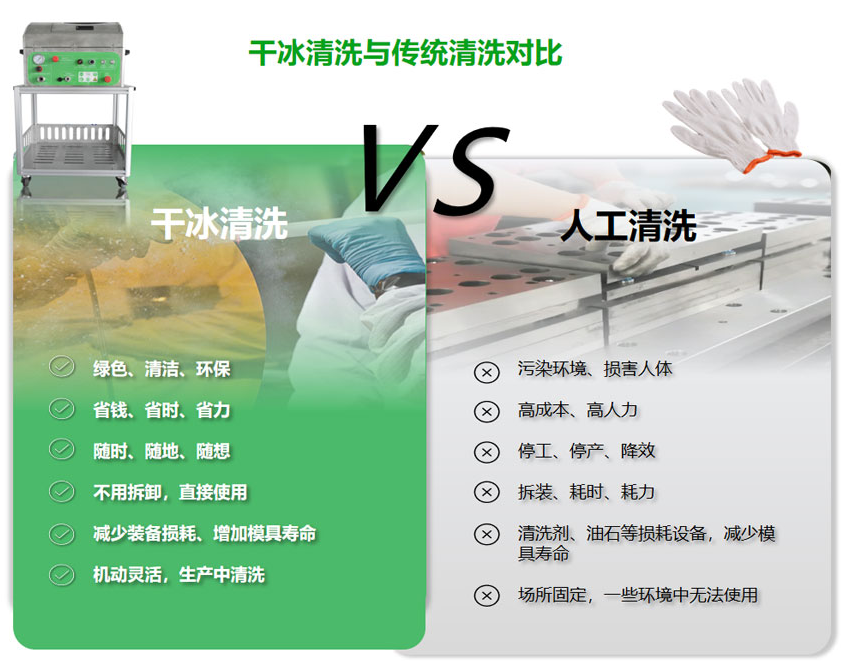

Dry ice cleaning machines are now being incorporated into cleaning processes by numerous manufacturers across a wide range of fields, including automotive, machinery, and even food manufacturing, for removing carbon, dust/powder, grease, and other contaminants.

Dry ice cleaning machines are a type of cleaning machine, and dry ice cleaning has experienced rapid development globally. The cleaning system uses high-pressure air to propel dry ice particles onto the work surface to be cleaned. The physical reaction caused by the temperature difference causes different substances to detach at different contraction rates.

When the -78°C dry ice particles come into contact with the dirt surface, they undergo a brittle explosion, causing the dirt to shrink and loosen. The dry ice particles then instantly vaporize and expand 800 times, generating a powerful peeling force that quickly and thoroughly removes the dirt from the surface. This achieves a fast, efficient, safe, and energy-saving cleaning effect.

Quick and Thorough Cleaning Methods

To ensure high-quality injection molding, thoroughly cleaning the complex cavities and vents of molds is a common challenge for plastic parts manufacturers. Residues inside the mold can cause numerous problems during injection molding, demolding, or labeling, potentially leading to increased product defects and mold damage.

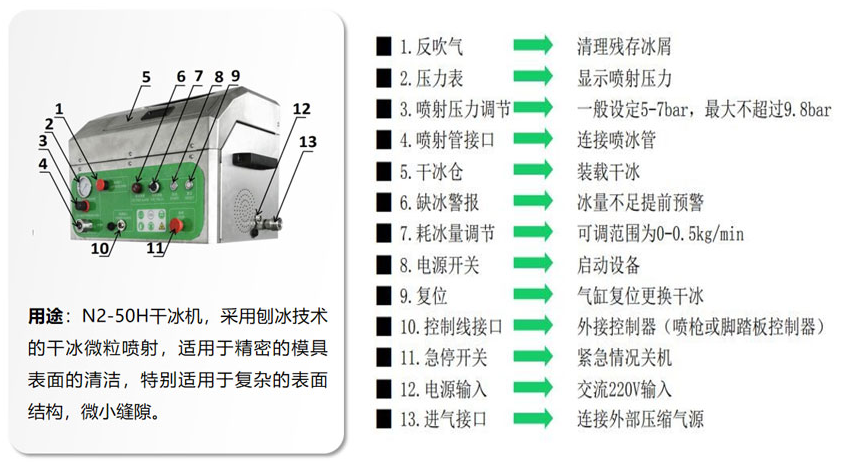

The tested dry ice machine operation

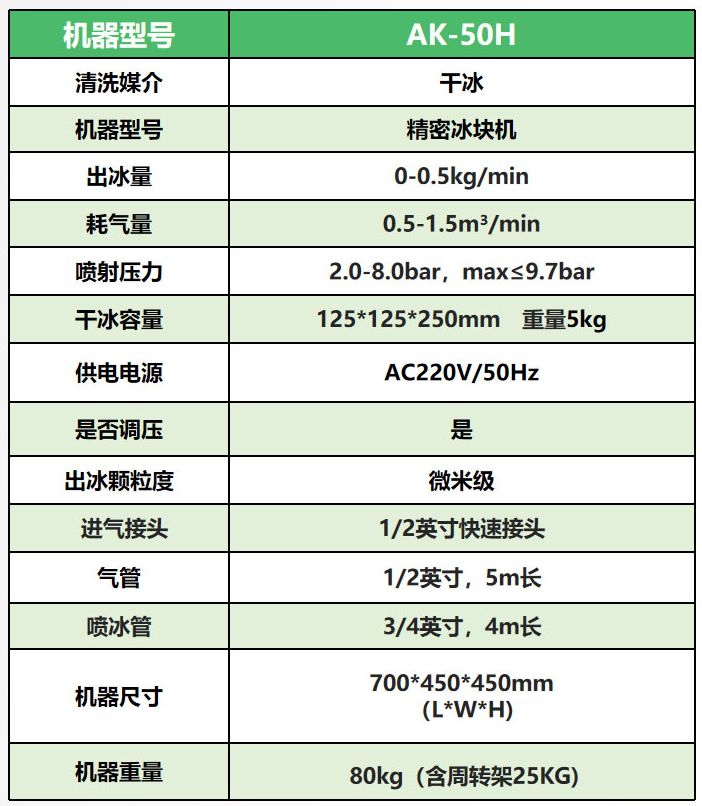

Parameters of the dry ice machine tested

Industrial maintenance and cleaning are critical to ensuring consistent production quality, minimizing downtime, and extending the lifespan of high-value equipment. In sectors such as automotive, electronics, food processing, and manufacturing, equipment surfaces—including molds, dies, and conveyor systems—accumulate grease, carbon deposits, rust, and other contaminants. Traditional cleaning methods such as abrasive blasting, chemical solvents, or manual scrubbing are often labor-intensive, inconsistent, and risk damaging sensitive surfaces. The AK-50H Dry Ice Cleaning Machine offers a modern, efficient solution, providing fast, non-abrasive cleaning while reducing environmental impact and operational downtime.

The AK-50H employs solid CO₂ pellets, commonly referred to as dry ice, as the cleaning medium. When projected at high velocity onto a surface, the pellets sublimate upon impact, transitioning directly from solid to gas. This process removes contaminants through three primary mechanisms: kinetic impact, thermal shock from rapid cooling, and expansion of sublimated gas lifting residues from the surface. The machine features adjustable air pressure, pellet flow control, and nozzle direction to ensure precise cleaning across both simple and complex geometries. Advanced models include automated cycle programming, multiple nozzle configurations, and integrated monitoring systems to deliver consistent, repeatable results.

The AK-50H is constructed with a durable pellet hopper, high-efficiency air compressor, corrosion-resistant piping, and precision nozzles. Components are engineered for continuous industrial use, with materials selected to withstand high pressure and potential chemical exposure. The system’s performance emphasizes cleaning efficiency while preserving delicate surfaces, making it suitable for molds, precision tooling, and sensitive electronics. Manufacturing practices prioritize airtight assembly, reliable control valves, and robust electrical systems, ensuring operational safety and minimal maintenance requirements.

Several factors influence the cleaning effectiveness of the AK-50H. Pellet size and air pressure must be optimized according to surface material and contamination type; larger pellets and higher pressure improve removal of heavy deposits but may risk surface abrasion on delicate components. Nozzle distance, angle, and cleaning duration also impact efficiency. Environmental conditions such as humidity and pellet storage quality are critical to maintain consistent cleaning performance. Regular inspection and maintenance of the air supply, pellet feed, and nozzle system are essential for achieving repeatable, high-quality results.

Selecting a reliable supplier for the AK-50H involves evaluating technical support, availability of spare parts, and expertise in integrating the machine into production lines. Suppliers should provide detailed guidance on optimal operating parameters, pellet quality, and maintenance schedules. Access to local and global support networks ensures minimal downtime and rapid troubleshooting. Compliance with safety regulations and environmental standards is essential for both machine operation and consumable sourcing, particularly in regions with strict industrial safety policies.

Industrial operators face challenges such as cleaning hard-to-reach surfaces, maintaining consistent pellet quality, and controlling CO₂ dispersion in confined areas. Manual or chemical cleaning alternatives often fail to provide repeatable results and may generate hazardous waste. The AK-50H addresses these issues by offering precise, automated, and environmentally friendly cleaning that minimizes labor risk and avoids surface damage.

The AK-50H is widely used across multiple sectors. In automotive manufacturing, it efficiently cleans injection molds, dies, and tooling without requiring disassembly. Electronics producers use it to clean circuit boards, housings, and sensitive equipment where solvents are undesirable. Food processing facilities apply dry ice cleaning to conveyors, molds, and packaging machinery, ensuring hygienic and residue-free surfaces. Across all industries, the AK-50H supports preventive maintenance, reduces production interruptions, and extends the operational life of high-value equipment.

The industrial cleaning market is increasingly oriented toward automation, sustainability, and smart integration. The AK-50H can be incorporated into robotic cleaning systems, enabling automated cleaning cycles that reduce operator exposure and labor costs. Innovations in pellet production, nozzle design, and airflow management are improving energy efficiency and cleaning precision. Future developments are expected to focus on intelligent monitoring, predictive maintenance, and integration into Industry 4.0 manufacturing systems, enhancing operational efficiency, safety, and data-driven process optimization.

Q1: Is the AK-50H safe for delicate surfaces?

Yes, adjustable pellet size, air pressure, and nozzle distance allow non-abrasive cleaning suitable for precision molds, electronics, and tooling.

Q2: Which industries benefit most from the AK-50H?

Automotive, electronics, medical device manufacturing, food processing, and general industrial maintenance benefit significantly.

Q3: How does dry ice cleaning compare environmentally to traditional methods?

Dry ice cleaning generates no secondary waste, is non-toxic, and uses CO₂ that sublimates harmlessly, reducing chemical disposal concerns.

The AK-50H Dry Ice Cleaning Machine is a transformative solution for modern industrial maintenance. By combining precise, non-abrasive cleaning with automation and reliable performance, it enhances equipment longevity, improves production efficiency, and ensures high-quality outcomes. As industries continue to prioritize automation, sustainability, and precision, the AK-50H will remain an essential tool for efficient, environmentally responsible industrial cleaning.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

@2024 Shanmo Precision Machinery (Kunshan) Co., Ltd. All rights reserved. Mold waterway cleaning machine,

electrolytic mold cleaning machine, mold cleaning machine manufacturer

TEL:+86 512-55001520

whats app:+86 15599099006 / +86 15599099098

E-Mail:sanmo030788@gmail.com

Add:No. 56, Yangjiaqiao Road, Zhoushi Town, Kunshan City Jiangsu Province

This website uses cookies to ensure you get the best experience on our website.