Welcome to visit the website of Sanmo Precision Machinery (Kunshan) Co., Ltd

whats app: +86 15599099006 / +86 15599099098

With advancements in industrial automation and rising labor costs, market demands for products are becoming increasingly stringent, and manufacturers are placing greater emphasis on controlling pass rates and hidden costs. This has led to the rise of cleaning machines that help improve product quality and enhance competitiveness.

Dry ice cleaning machines are now being incorporated into cleaning processes by numerous manufacturers across a wide range of fields, including automotive, machinery, and even food manufacturing, for removing carbon, dust/powder, grease, and other contaminants.

Dry ice cleaning machines are a type of cleaning machine, and dry ice cleaning has experienced rapid development globally. The cleaning system uses high-pressure air to propel dry ice particles onto the work surface to be cleaned. The physical reaction caused by the temperature difference causes different substances to detach at different contraction rates.

When the -78°C dry ice particles come into contact with the dirt surface, they undergo a brittle explosion, causing the dirt to shrink and loosen. The dry ice particles then instantly vaporize and expand 800 times, generating a powerful peeling force that quickly and thoroughly removes the dirt from the surface. This achieves a fast, efficient, safe, and energy-saving cleaning effect.

A Quick and Thorough Cleaning Method

To ensure high-quality injection molding, thoroughly cleaning the complex cavities and vents of molds is a common challenge for plastic parts manufacturers. Residues inside the mold can cause numerous problems during injection molding, demolding, or labeling, potentially leading to increased product defects and mold damage.

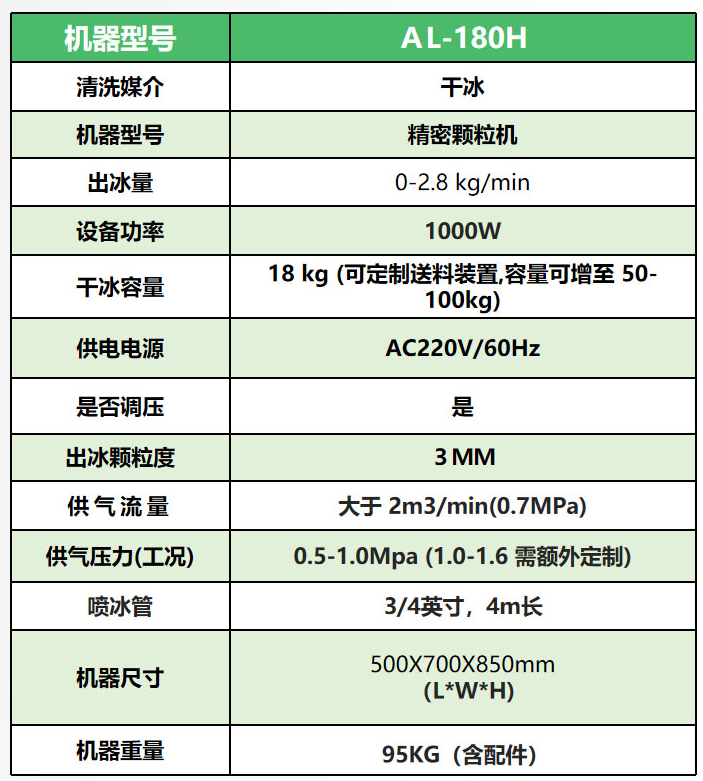

Dry Ice Machine Parameters Tested

In modern manufacturing, equipment cleanliness directly impacts product quality, operational efficiency, and equipment lifespan. Industries such as automotive, electronics, aerospace, and food processing face frequent contamination issues, including grease, rust, carbon deposits, and adhesive residues. Traditional cleaning methods, such as chemical solvents, manual scrubbing, or abrasive blasting, often risk surface damage, generate hazardous waste, and require substantial labor. Increasing regulatory pressure for environmentally friendly practices and rising demand for operational efficiency have driven interest in advanced cleaning technologies. The dry ice cleaning machine has emerged as a preferred solution, offering precision cleaning without secondary waste or abrasive impact.

The dry ice cleaning process utilizes solid carbon dioxide pellets as the cleaning medium. Upon high-velocity impact with the surface, the dry ice sublimates from solid to gas. This sublimation provides three cleaning mechanisms: kinetic impact dislodges surface contaminants, rapid thermal contraction loosens stubborn residues, and gas expansion lifts debris away. Advanced systems incorporate adjustable air pressure, pellet flow rates, and directional nozzles, allowing operators to target both broad and intricate surfaces. Some machines integrate automated cleaning cycles, programmable nozzle paths, and real-time monitoring to ensure repeatable, uniform results across different applications.

Dry ice cleaning machines consist of a pellet hopper, high-performance air compressor, corrosion-resistant tubing, and precision nozzles. The hopper stores CO₂ pellets and feeds them consistently to the cleaning head. The air supply system ensures stable delivery at controllable pressure, while nozzles are designed for precise coverage, even in complex mold cavities or electronic assemblies. Machines are constructed from stainless steel and industrial-grade polymers, providing resistance to corrosion and mechanical stress. Manufacturing standards emphasize airtight assemblies, reliable valve control, and durable electrical systems, ensuring minimal maintenance and long operational life.

Effective dry ice cleaning depends on multiple variables. Pellet size, air pressure, nozzle angle, and cleaning duration must align with surface material and contamination type. Larger pellets and higher air pressure accelerate removal of heavy deposits but may risk sensitive surfaces. Environmental factors, such as humidity and pellet storage conditions, also affect performance. Consistent maintenance of the hopper, air compressor, and nozzle system is essential to sustain high-quality cleaning. Operators should calibrate machines for each application to achieve optimal results while minimizing resource consumption.

Selecting a reliable supplier for dry ice cleaning machines requires evaluating technical support, availability of spare parts, and expertise in installation and integration. Reputable suppliers provide guidance on optimal operating parameters, pellet specifications, and preventive maintenance schedules. Accessibility to local or global support networks is critical for minimizing downtime. Compliance with safety and environmental regulations, including handling CO₂ and operating pressurized systems, should also factor into supplier evaluation.

Despite its advantages, dry ice cleaning faces challenges. Operators must safely manage CO₂ sublimation in confined spaces and prevent cold burn hazards. Achieving consistent cleaning results on complex geometries requires precise nozzle control and proper pellet calibration. Equipment downtime for maintenance or pellet replenishment can impact production schedules if not carefully planned. However, these challenges are mitigated through training, automation, and integrating the machine into preventive maintenance routines.

Dry ice cleaning machines are widely adopted across multiple industries. In automotive manufacturing, they clean molds, dies, and production tools without disassembly. Electronics and semiconductor production use dry ice cleaning to remove flux residues and particulate contaminants without introducing moisture. Food processing facilities employ these machines to clean conveyors, mixers, and packaging equipment, maintaining hygiene standards without chemicals. Additionally, aerospace and industrial machinery sectors use dry ice cleaning to remove carbon build-up from turbines, engines, and precision components, ensuring operational efficiency and extended equipment lifespan.

The industrial cleaning market is trending toward automation, environmental sustainability, and integration with smart manufacturing systems. Dry ice cleaning machines are increasingly paired with robotic arms or conveyor systems for automated, repeatable cleaning cycles. Improvements in nozzle design, pellet quality, and airflow management are enhancing energy efficiency and precision. Future developments may include AI-assisted monitoring, predictive maintenance integration, and remote operation capabilities, aligning with Industry 4.0 objectives. As industries prioritize productivity, safety, and eco-friendly operations, dry ice cleaning machines will remain a key technology for industrial maintenance.

Q1: Is dry ice cleaning safe for delicate surfaces?

Yes, adjustable pellet size, air pressure, and nozzle distance allow non-abrasive cleaning suitable for sensitive components and molds.

Q2: Which industries benefit most from dry ice cleaning?

Automotive, electronics, aerospace, food processing, and heavy machinery industries gain the greatest operational and environmental benefits.

Q3: How does dry ice cleaning compare environmentally to traditional methods?

Dry ice cleaning produces no secondary waste, is non-toxic, and uses CO₂ that sublimates harmlessly, reducing chemical disposal concerns.

The dry ice cleaning machine represents a transformative approach to industrial cleaning. By combining precise, non-abrasive cleaning with automation and reliable performance, it reduces downtime, extends equipment lifespan, and ensures operational efficiency. Its versatility across industries, environmental benefits, and compatibility with modern manufacturing trends make it an essential tool for forward-looking industrial operations.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

@2024 Shanmo Precision Machinery (Kunshan) Co., Ltd. All rights reserved. Mold waterway cleaning machine,

electrolytic mold cleaning machine, mold cleaning machine manufacturer

TEL:+86 512-55001520

whats app:+86 15599099006 / +86 15599099098

E-Mail:sanmo030788@gmail.com

Add:No. 56, Yangjiaqiao Road, Zhoushi Town, Kunshan City Jiangsu Province

This website uses cookies to ensure you get the best experience on our website.